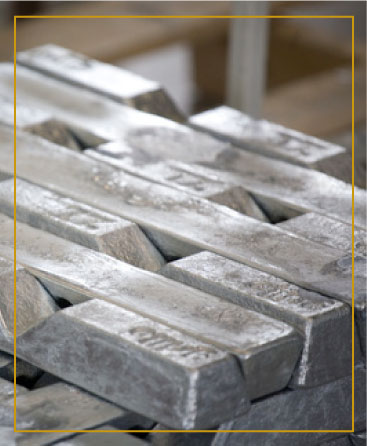

Aluminium Ingots

The lightweight nature and excellent versatility of aluminium, in addition to the fact it is easy to machine and is highly resistant to corrosion, make it one of the most widely used metals in the industrial sector. And what´s more, aluminum has another decisive advantage: it is completely recyclable.

Aluminum ingots are mainly used in the foundry sector and in the electrical conductor manufacturing industry.

Aluminum features different degrees of purity. Pure aluminum ingots are ideal for casting and are used in specific fields of activity including the naval sector and the manufacture of nautical anodes, among others.

Moreover, in some cases aluminum alloys provide a better solution for the manufacture of parts using moulding processes. Hence, a large part of the aluminum ingots used in the industrial sector are made of aluminium alloyed with other metals.

The most commonly used elements for the manufacture of aluminum alloy ingots are magnesium, silicon, manganese, zinc and copper.

Clerins Aluminum Ingot Quality Certification

Our aluminium ingots are 99.9% pure, which makes them ideal for all the aforementioned uses and, in particular, for ensuring the required standards of quality of the primary alloys used by our foundry clients.

You can access the quality certificate for our aluminium ingots here.

Tailor-made aluminium ingots

Pure aluminium is normally supplied in 25-kg ingots. Moreover, we can always manufacture other weights and sizes of ingots in accordance with your needs.

Examples of commonly used alloys, which we always have in stock at our warehouses for immediate delivery, include 2630-A aluminum alloy ingots (EN AC 46.000) and 2520 aluminum alloy ingots (EN AC 44.100).

Our aluminum alloy ingots meet the applicable international specifications.

Our warehouses are permanently stocked with aluminium ingots of around 10 kg in weight in order to ensure rapid, efficient delivery.Moreover, we can always manufacture other weights and sizes of ingots in accordance with your needs.